Table of contents

- The problem is a decline in competitiveness due to a disconnect between management and manufacturing workplace awareness.

- Differences in security thinking between IT and OT that hinder DX

- Security concept in IT

- Security concept in OT

- Operational development is required based on the differences between IT and OT

- summary

The problem is a decline in competitiveness due to a disconnect between management and manufacturing workplace awareness.

According to the Cabinet Office’s 2013 Annual Economic and Fiscal Report, the ROA (Return on Total Assets) of Japanese companies’ production facilities remains at a low level compared to Germany and France.

In addition, price competition is currently underway with emerging powers such as China, Thailand, and Vietnam. Under these circumstances, there is a need for flexible manufacturing that can deliver value-added products to the world that meet market needs. We will have to shift from product-out manufacturing to market-in small-scale production, and then to customer-in individual production.

In order to realize flexible manufacturing, close collaboration between management and manufacturing sites is essential. We need to create a system that allows the workplace to understand management decisions and achieve the desired manufacturing goals. However, the prolonged economic downturn also had an impact, creating a situation where manufacturing sites were exhausted by the excessive demands placed on them by management, which led to a rift in the mindsets of both parties.

Rather than operating the production site with unilateral support, management is being forced to accurately grasp and understand the situation at the manufacturing site one by one, and utilize this knowledge in making management decisions.

Differences in security thinking between IT and OT that hinder DX

Nowadays, it has become unimaginable to live without using the Internet, and we have entered an era in which not only people but also things are connected to the Internet. Therefore, a wide range of security measures are essential. However, IT and OT have very different approaches to security.

Security concept in IT

IT (Information Technology) is information technology, and is a general term for technology related to computers and data communications. It often refers to technology using computers and the Internet that is useful in work and life, and a similar term is ICT (Information and Communication Technology). As you can see from the inclusion of the word “Communication,” ICT refers to technology that is primarily used by humans and is useful for communication.

Since IT is a technology that is often used by humans, it is important to provide value to humans through immediacy and convenience. Specifically, there is a need for technology that allows users to quickly and easily select what they are looking for from large amounts of data, and that allows them to easily obtain information at any time.

In addition, if the “impact on human life, social or economic impact, or impact from the perspective of business continuity” is judged to be small, security patches and vulnerability scans may be applied even while the IT system is in operation. It is also assumed that this will be done.

Security concept in OT

OT (Operational Technology) is a technology for controlling the state of things and things, such as processing equipment control, power generation equipment, and railway control networks. For example, in the case of manufacturing equipment, we measure the position of valves and belt conveyors, temperature, pressure, flow rate, etc. as operational data and perform appropriate control.

The objects controlled by OT include things such as production lines and transportation networks, which would cause significant business damage and social impact if control were to stop. Therefore, stable operation and system redundancy are inevitably required, and operation must be done carefully. Due to this characteristic, it is not recommended to scan for vulnerabilities while the system is running, as it may cause harmful effects by applying security patches and may cause the system to stop.

Operational development is required based on the differences between IT and OT

As mentioned above, IT and OT have different goals, so you may encounter various differences when considering their fusion.

For example, a single term may have a different meaning between IT and OT. The term “FW” means firewall in IT and firmware in OT. As you can see, the cultures of OT, where the goal is more redundancy and reliability, and IT, whose goal is to release as quickly as possible and provide value to users, are very different.

Here are some easy-to-understand examples of the differences between the two cultures. Agile methods are attracting attention in IT, where new features are released in a short period of time while quickly identifying market needs.

This approach focuses on providing the value the user needs in the minimum amount of time and with the minimum amount of functionality. Therefore, system redundancy and security requirements are not considered as important as they are considered “issues that are difficult to link to user value.” From the perspective of those involved in OT, this kind of thinking may seem like a completely different world.

Overcoming these challenges, the benefits of merging IT and OT are wide-ranging. Until now, it was only possible for people in charge at the production site to understand the operating status and operating rates of industrial machinery and transportation equipment. However, when these data are transmitted to management through networks as data, they can be used as material for various management decisions.

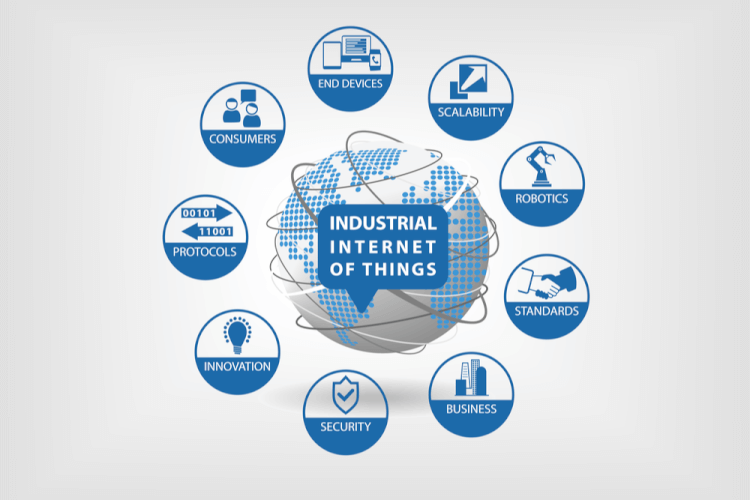

When IT and OT are fused and the IoT (Industrial Internet of Things) at manufacturing sites is realized, manufacturing sites and management will be connected in real time. In production management and inventory management, management decisions can be made based on real-time data from the field.

The fusion of IT and OT will become a weapon for realizing more flexible and strategic manufacturing, and will greatly contribute to the DX transformation of the manufacturing industry.

summary

In Japan’s manufacturing industry, skilled workers at the manufacturing site have been able to produce large quantities of high-quality products through their experience and intuition. In future society, new manufacturing sites that integrate IT and OT will be required to make better use of the skills of skilled personnel.